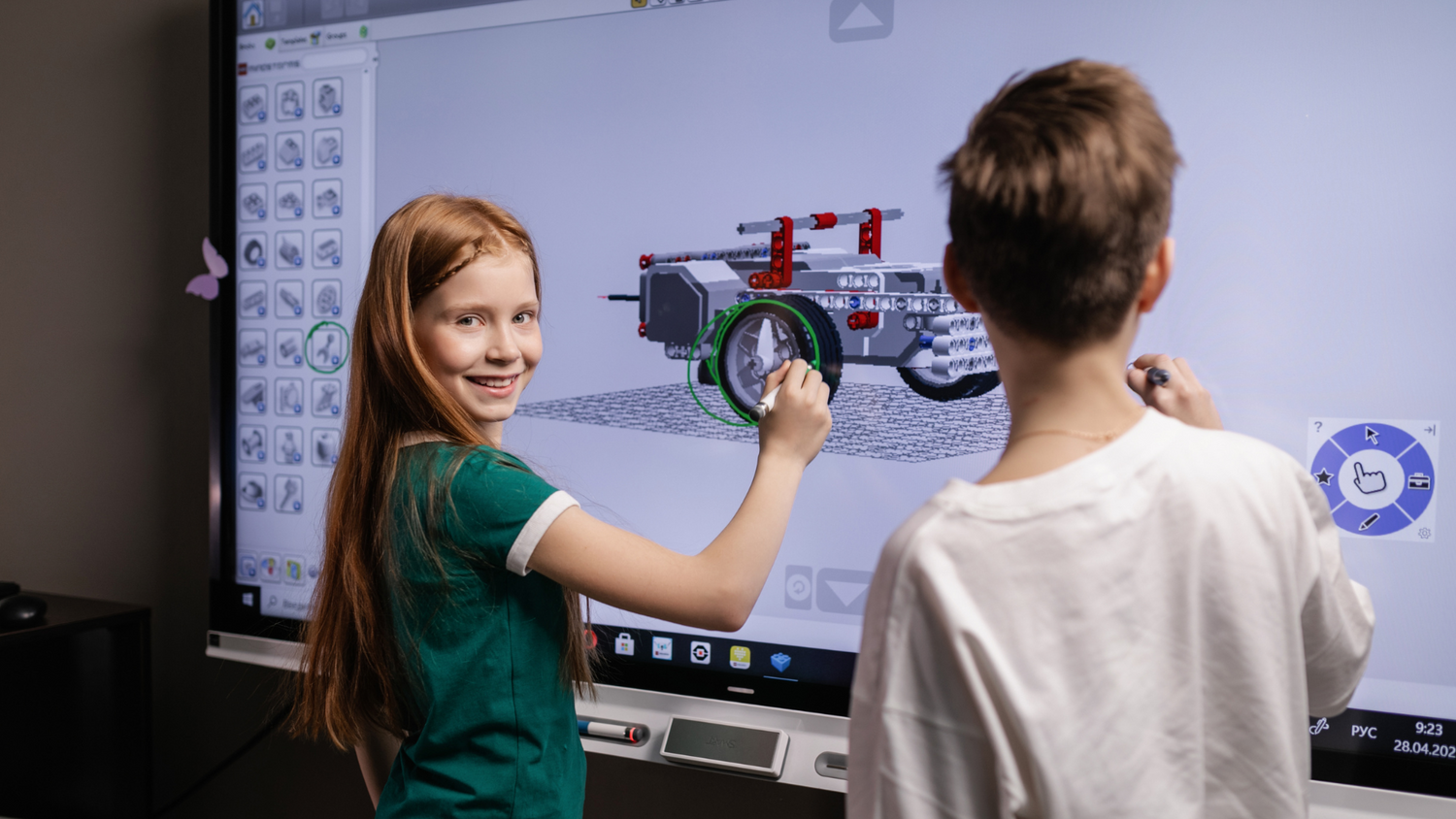

Introduction:

Freeze-drying may be a high-tech process, but behind the scenes, it’s a carefully engineered system of physics, material science, and precision control. Creating the perfect freeze-dried candy requires an understanding of how different ingredients react under extreme conditions. In this post, we’ll explore the engineering behind making crunchy, puffed-up treats.

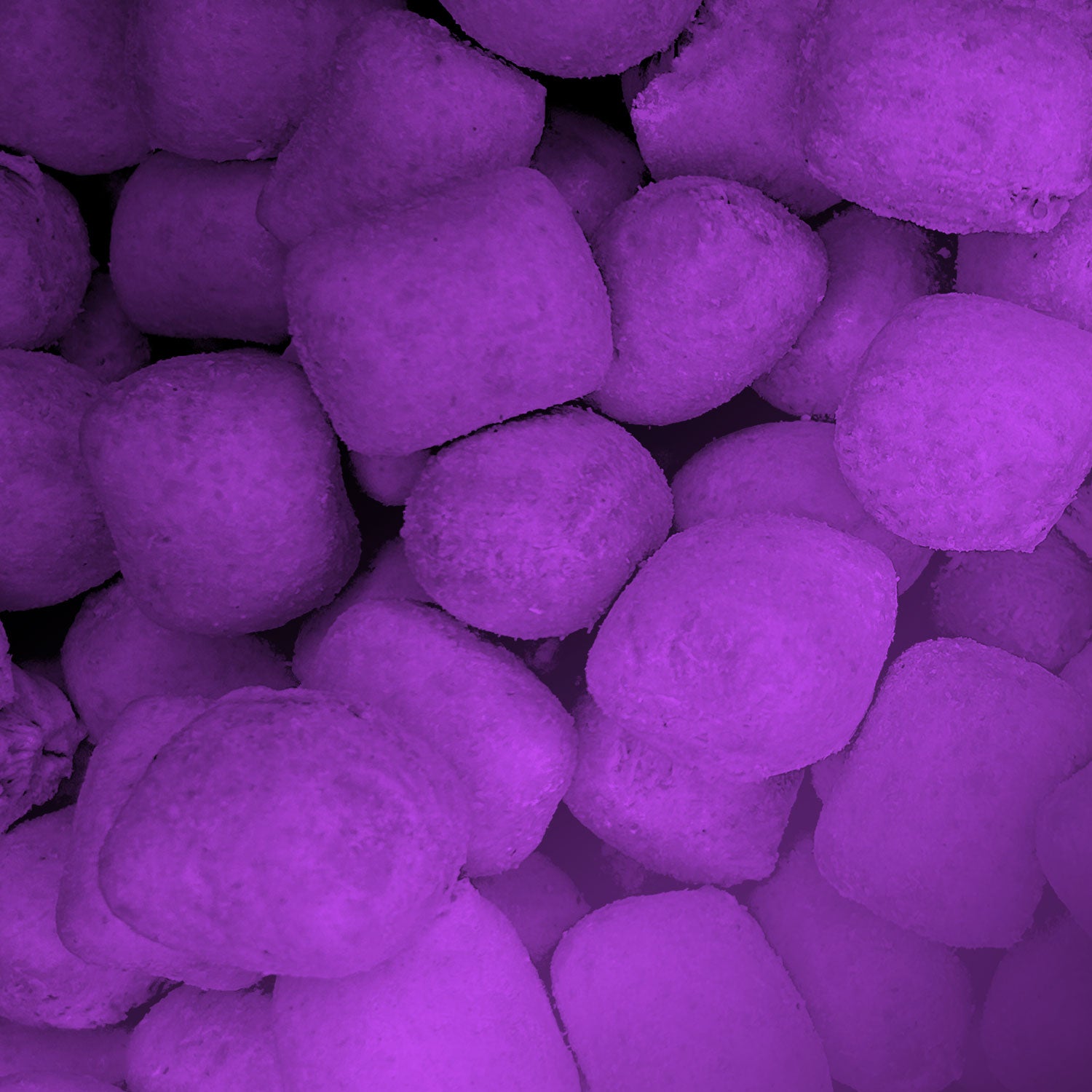

The Structural Science of Candy

Not all candies freeze-dry the same way. Their physical structure, sugar content, and water composition all play a role in the final product. Engineers must consider:

- Density & Composition: Aerated candies (like marshmallows) expand due to trapped air pockets, while denser candies (like gummies) resist expansion.

- Surface Area: Candies with more surface area dry faster, while compact candies take longer to freeze-dry fully.

- Sugar & Fat Content: High-sugar candies expand dramatically, whereas fatty candies struggle with the freeze-drying process due to their resistance to water sublimation.

Optimizing Freeze-Drying Efficiency

Engineers work to refine freeze-drying processes for maximum efficiency by:

- Controlling Temperature & Pressure: Proper settings ensure the candy doesn’t collapse or burn.

- Layering in Trays: Arranging candies for even exposure to vacuum and heat ensures consistency in expansion.

- Adjusting Drying Time: Some candies dry faster than others, requiring precision timing to avoid over-drying or structural failure.

Why Do Some Candies Puff Up?

Puffed-up freeze-dried candy is an engineering marvel! The key factors include:

- Expansion of Ice Crystals: Water expands when frozen, and as it sublimates, it leaves behind tiny air pockets, making candy airy and crispy.

- Weak Internal Structure: Some candies, like taffy and nougat, lack strong internal bonds, allowing them to expand significantly.

- Rate of Sublimation: A faster sublimation process can cause a more dramatic puffing effect, depending on the candy’s molecular composition.

Engineering the Ultimate Crunch

Texture is a key factor in the freeze-drying experience. Engineers focus on:

- Crisp vs. Crunchy: The thickness and structure of the candy determine whether it becomes airy and crispy (like Skittles) or dense and crunchy (like caramel chews).

- Moisture Control: Even small amounts of remaining moisture can affect the final texture, making precision dehydration crucial.

- Shelf Stability: Properly engineered freeze-drying ensures a long shelf life by removing nearly all water while preserving color and flavor.

Fun Engineering Fact!

A single freeze-dried Skittle can expand over twice its original size, thanks to the rapid sublimation process!

Conclusion:

Freeze-drying candy is as much about engineering as it is about science. Understanding the structural properties of different treats helps create the light, crunchy, and uniquely puffed-up candies we love.

Next up in our STEAM series: Art (A)—how freeze-drying turns candy into a creative masterpiece!